Jean-François Podevin

It’s a sweltering late February afternoon when I pull into the Esso gas station in the tiny town of Bukit Merah, Malaysia. My guide, a local butcher named Hew Yun Tat, warns me that the owner is known for his stinginess. “He’s going to ask you to buy him tea,” Hew says. “Even though he owns many businesses around here, he still can’t resist pinching pennies.”

An older man emerges from the station office. His face and hands are mottled with white patches, his English broken.

“I’ll talk to you,” the man says, “but only if you buy me tea.” He grins.

“You should be ashamed of yourself,” says Hew, laughing. “A rich man like you.”

At a bustling open-air café nearby, we order tea and ais kacang, giant shaved-ice desserts laden with chopped-up jello and sweet, sticky red beans. I dig in, but the station owner—I’ll call him Esso Man, since he doesn’t want me to use his real name—is moodily stirring his into a slushy puddle. We’re here to ask him about something he doesn’t like to talk about: a job he did 30 years ago, when he owned a trucking company. He got a contract with a local industrial plant called Asian Rare Earth, co-owned by Mitsubishi Chemical, that supplied special minerals to the personal electronics industry.

Esso Man couldn’t believe his luck. He wasn’t a rich man back then, and Asian Rare Earth offered three times as much as his usual gigs, just for trucking waste away from the plant. They didn’t say where or how to dump the waste, and he and his three drivers were paid by the load—the quicker the trip, the more money they earned. “Sometimes they would tell us it was fertilizer, so we would take it to local farms,” Esso Man says. “My uncle was a vegetable farmer, so I gave some to him.” Other times, the refinery officials said the stuff was quicklime, so one driver painted his house with it. “He thought it was great, because it made all the mosquitoes and mice stay away.”

In fact, Esso Man and his drivers were hauling toxic and radioactive waste, as they’d discover a year later, when Asian Rare Earth tried to build a dump in a neighboring town. Residents there began to protest, and a few activists took a Geiger counter to the plant, where they found levels of radiation that were off the charts—up to 88 times higher than those allowed under international guidelines. In 1985, after residents sued, the government ordered the plant to be closed until Asian Rare Earth cleaned up its mess.

Two years later, the site still wasn’t completely clean, but Asian Rare Earth got permission to reopen the plant. The protests began anew, and Hew, one of the leaders of the opposition, was jailed for two months. When he got out he snuck back to the protests, which grew in size and popularity. In 1992, the residents who’d sued Asian Rare Earth won a permanent injunction against the plant. It was overturned by the Supreme Court, but Asian Rare Earth had had enough, and it pulled out of Bukit Merah and shut down operations entirely.

But by then, Hew says, the villagers were anxious. Pregnant women living near the plant had miscarried; some gave birth to children who were sickly, or mentally disabled, or blind. Other children in the village developed leukemia.

Officials told residents that the waste was properly disposed of. But in 2010, a local paper visited Asian Rare Earth’s dump site and found 80,000 drums containing 4.2 million gallons of radioactive thorium hydroxide. That year, Mitsubishi broke ground on a secure, underground storage area to properly house the waste of its former subsidiary. The New York Times recently called the $100 million Asian Rare Earth recovery “the largest radiation cleanup yet in the rare earth industry.”

(The images in the slideshow below, from the awesome PeriodicTable.com, are used by permission.)

As we finish our dessert, I ask Esso Man about the white patches on his skin, which started appearing several years after he’d worked with Asian Rare Earth’s waste. His doctors speculate they might have to do with his exposure to radioactivity, he says, but they can’t be sure. Such medical guesswork is common in Bukit Merah, since no one has ever formally studied the impact of radiation exposure among the village’s 11,000 residents. (Mitsubishi denies any health effects.) And anyway, sometimes Esso Man thinks it might just be stress that’s causing his skin condition. “I feel regret about working for that company,” he says glumly. “I feel bad that I gave people all that toxic waste. Even my own uncle.” All of Esso Man’s drivers have died young—not one lived past his 50s. “I don’t know why they died and I am still alive.”

After we drop Esso Man back at his gas station, Hew takes me to the nearby home of Lai Kwan, a local woman who worked as a bricklayer at the Bukit Merah plant while she was pregnant in 1982. Hunched over and walking slowly, she looks older than her 69 years. In her modest living room, photos of her eight children, now grown, line the walls. In the corner is a small cluster of flowers and vials of powder that I take for a Buddhist shrine, but Lai Kwan explains that they are gifts from her friends and neighbors, and that the vials contain chicken essence, known in Chinese medicine for its healing properties.

Lai Kwan recalls that soon after she started working in the plant, she heard rumors from the Japanese workers that the materials they were refining were dangerous. Several of her coworkers miscarried, and when she found out she was pregnant, she worried about her baby’s health. So a few months later, she quit. Her son, Cheah Kok Liang, was born in 1983, profoundly retarded and nearly blind. Lai Kwan’s husband left when the boy was a toddler. Now 29, Cheah still lives at home and requires full-time care. He’s suffered from frequent chest infections his whole life, but it’s hard to tell when he’s getting ill, since he can’t communicate. I ask to meet him, but Lai Kwan explains that he is sleeping. “If he were awake right now, I couldn’t be talking to you.”

What will happen to Cheah when she can’t care for him anymore? “It’s getting harder now,” she says. “He’s heavy, and I have arthritis.” Money is tight—since Lai Kwan can’t read or write very well, she’d only be able to find work at a factory, and she can’t leave Cheah alone for a whole shift. A few months ago, a local politician visited and promised to help, but “every time I call she says she is too busy,” says Lai Kwan, showing us a picture of the politician and her son in the local newspaper.

A doctor from Kuala Lumpur tells me that he visited Bukit Merah to treat the eight children there who developed leukemia, seven of whom have died. Though there has never been a formal epidemiological study of the area, radiation exposure is a known cause of childhood leukemia, and no local I talked to could remember a single case of the disease before the plant opened.

About six weeks after I get back to the United States, I receive word that Cheah passed away suddenly. The cause of his death is still unknown.

I HAVE COME TO MALAYSIA because of my iPhone. I already knew that behind its sleek casing lurked a problematic history. I’d read the stories about Apple’s Chinese factories—about teenage girls working 15-hour shifts cleaning screens with toxic solvents, about suicides among exhausted workers whose lives are no longer their own. But I had a much dimmer idea of my phone’s history before the Foxconn plant—where did those components they put together come from? What were its guts made of? My phone’s shady past, it turned out, began long before it was assembled in a Chinese factory. The elements used to power all our high-tech gadgets come from a very dirty industry in which rich nations extract the good stuff from the earth—and leave poor countries to clean up the mess.

“Never again” is a common refrain among Bukit Merah residents who have lived through 20 years of Asian Rare Earth aftermath. But the Malaysian government doesn’t agree. In 2008, it approved an Australian company’s plan to build a brand new rare-earth refinery on the country’s east coast. The company, Lynas Corporation, will do its mining in Australia, but it will refine the rare earths—a process that generates vast quantities of toxic and radioactive waste—in Kuantan, Malaysia, a sleepy coastal city in a state where the average resident makes $7,314 a year. When completed, the plant will be the largest of its kind, meeting a full fifth of the world’s rare-earth demand. Its waste will not be permanently stored in an underground facility. Instead, toxic wastewater will be treated and released into the productive fishing grounds of the South China Sea, home to more than 3,300 species of fish. As for the plans for the radioactive solids? Well, they remind people all too much of what happened in the days of Esso Man.

To the Malaysian government, the Lynas plant represents an opportunity to become a major player in one of the most lucrative, fastest-growing industries in the world. In the 20 years since the Bukit Merah plant closed, demand for rare earths has increased tenfold, from roughly $1 billion to $10 billion today. A recent report predicted it to grow another 36 percent by 2015.

THE 17 RARE-EARTH ELEMENTS aren’t as rare as was thought when they were discovered in the 1800s. But they often perform specific, crucial functions. For example, “virtually all polished glass products” depend on cerium, according to the US Geological Survey; the element is also vital to catalytic converters. Other rare earths help form the world’s strongest magnets. If you hold a chunk of magnetized neodymium, a chunk a few feet away will fly through the air to meet it. Because rare-earth magnets are so strong, a little goes a long way. They’re the reason your smartphone has computing power that would have filled two rooms just 30 years ago yet today fits in the palm of your hand.

Walk down the aisles of your local Best Buy and you’ll be hard-pressed to find a phone, laptop, or TV that doesn’t contain at least one of the rare earths. The elements are also key to all kinds of green technology: Neodymium is found in wind turbines; hybrid and electric cars often contain as many as nine different rare earths. Yttrium can form phosphors that make light in LED displays and compact fluorescent lightbulbs. Rare earths are also crucial for defense technology—radar and sonar systems, tank engines, smart bombs.

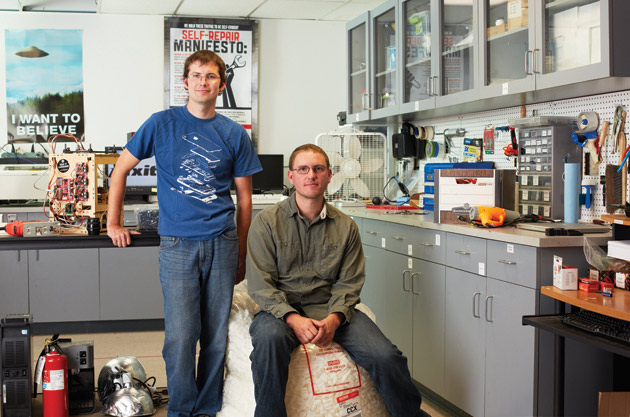

Elements of Style

The rare earths lurking inside your hybrid car and smartphone.

But here’s the catch. Rare earths always occur alongside the radioactive elements thorium and uranium, and safely separating them is a complex process. Miners use heavy machinery to reach the raw ore, which contains anywhere between 3 and 9 percent rare earths, depending on the deposit. Then the ore is taken to a refinery and “cracked,” a process wherein workers use sulfuric acid to make a liquid stew of sorts. The process is also hugely water- and energy-intensive, requiring a continuous 49 megawatts (enough to power 50,000 homes) and two Olympic swimming pools’ worth of water every day.

Workers then boil off the liquid and separate out the rare earths from rock and radioactive elements. This is where things get dangerous: Companies must take precautions so that workers aren’t exposed to radiation. If the tailings ponds where the radioactive elements are permanently stored are improperly lined, they can leach into the groundwater. If they are not covered properly, the slurry could dry and escape as dust. And this radioactive waste must be stored for an incomprehensibly long time—the half-life of thorium is about 14 billion years, and uranium’s is up to 4.5 billion years. Reminder: Earth itself is 4.5 billion years old.

Not coincidentally, the refining tends to happen in areas where weak environmental rules mean that companies can process the elements on the cheap. Take the Baotou region of Inner Mongolia, where most of China’s rare-earth mines are clustered, and where waste has leached into waterways and irrigation canals, according to several independent investigations. Communities around one former mine in Mongolia blame at least 66 cancer deaths on leaked radioactive waste, and local people complain that their hair and teeth have fallen out.

All this so that my friends and I can settle an argument about the order of Metallica’s first three albums from the comfort of our bar stools.

KUANTAN, THE TOWN WHERE LYNAS has built its new rare-earth refinery, is a popular vacation spot—laid-back and unpretentious, with uncrowded beaches and delicious seafood. By early fall, Lynas’ rare-earth ore will begin to arrive.

Shipping ore thousands of miles is extremely expensive. But the company says the cheaper labor, electricity, and chemicals in Malaysia make it worthwhile. Malaysians who oppose the plant see a much more troubling dynamic. “Australia is a first-world country that wants the developing world to do its dirty work,” says Fuziah Salleh, Kuantan’s parliamentary representative and an outspoken critic of the Lynas project. “Our environmental laws are very lax, and Lynas knows exactly where to take advantage of it. If you look at Australia, there are very strict laws about controlling the waste, dust, and air quality. But here in Malaysia—even if we have those laws—it is very hard to enforce.”

Lynas emphasizes that this refinery will be “completely different to the Bukit Merah rare-earths plant” and that “there are now much higher standards in place which mean Bukit Merah could never be repeated.” Last year, the Malaysian government asked the International Atomic Energy Agency to recommend a list of 11 safety requirements and standards that should be in place in order to operate. But Lynas was allowed to open its refinery without meeting the most important one—a long-term storage solution for the waste. Instead, Lynas says it will treat the highly acidic liquid waste before releasing it into waters that support a thriving mangrove ecosystem and fish that local residents depend on.

That hasn’t done much to reassure the people of Kuantan. “Lynas doesn’t care what happens to us,” one fisherman tells me. “They just want their money.” They are also less than thrilled that their government has promised Lynas a 12-year tax holiday.

But even more dubious is what Lynas proposes to do with the radioactive solids: Isolate them—the company is not forthcoming with any details as to how—before diluting them with soil or concrete and selling the mixture as fertilizer or construction materials.

“They have yet to establish it is either economically or practically feasible,” says Dr. Peter Karamoskos, a radiation safety adviser for the Australian government. Noting that Lynas’ waste is six times as radioactive as levels recognized as safe, he does a quick calculation: “By the end of 10 years of 1 million tons of waste, where are you going to find 6 million tons to dilute it with? Where are you going to find the clients to take up that stuff? Where are their contracts? Any builder who touched this waste would be out of business immediately. You can argue that if you diluted it adequately you could use it. However, remember the problem is that buildings get demolished. Once you start doing that, you release that back into the environment.”

No wonder the plant has become a rallying cause for the opposition parties in upcoming elections. Even in Kuala Lumpur, 150 miles from the plant, I saw bumper stickers bearing the words “Save Malaysia! Stop Lynas!” and here in Kuantan, the slogan is everywhere—on flyers in store windows, on T-shirts, and even on umbrellas.

Among the local protesters is an environmental consultant and Kuantan native named Lee Tan, who now lives mostly in Australia but hasn’t forgotten a single crevice of her hometown. A stout, cheerful woman in her early 50s, Tan takes me to a roadside fish stand in the nearby village of Sungai Karang, where a handful of families sit around plastic tables as kids dart around underfoot and a few hungry cats lick their chops near the trash area out back. This is a Muslim village, and Tan and I are the only women not wearing a tudung, the Malaysian headscarf. The shop’s owner, 31-year-old Jamil Jusuf, is making his specialty: fried fingers of selayang and padang fish dusted with spicy meal, wrapped tightly in leaves and grilled over an open flame. Jusuf says he first heard about the refinery from tourists. “They told me that the waste will go right where I get my fish from,” he says.

Over at a fishing dock on the Balok River, just a few hundred yards from Lynas’ waste release site, a fisherman says that he has heard that the opposition party, which is largely made up of ethnic Chinese, is using the Lynas issue to get more votes; the Malay-dominated government has been very supportive of Lynas. He produces a beat-up booklet bearing the Lynas logo. “Lynas has come here many times to hand out pamphlets,” he says. Later, Tan translates the pamphlet for me. “The Lynas plant will not be dangerous to the public, the surrounding area, or its workers,” declares one bolded heading.

The next day I snag a meeting with a senior government spokesman, who agrees to speak if I don’t publish his name. I ask him what locals will gain from having the plant nearby. “A lot, a lot,” he says, before admitting that Lynas will only employ about 300 people. “But because Lynas is here, some other industries will also come.”

“Which ones?”

“Siemens,” he says. I ask whether the German electronics conglomerate has made a formal commitment. He concedes that it hasn’t.

“So have any other companies officially said they would come?”

“Thus far, no other commitments yet.”

And what of the plant’s potential chilling effect on tourism? He brushes that aside. “Fears created by the opposition have influenced a very tiny segment of the people, especially among the Chinese,” he says. “The Malays are not worried, because we have been telling them that this project is safe, so why would they fear?”

FROM KUANTAN, I HEAD BACK to noisy, frenetic Kuala Lumpur. In my hotel room, I can hear tourists at the karaoke bar next door belting out Whitney Houston hits. Tourism accounts for around 6.7 percent of the country’s GDP. Over the last decade, the number of foreign tourists has more than doubled, making it the ninth most visited country in the world, just shy of Germany. That it’s a Muslim country makes it an especially popular destination for visitors from the Arab world. I wonder if radiation fears will hurt tourism.

Most of the 12 rare-earth experts I’ve spoken to say it’s technically possible for Lynas to scrub its waste of all the toxic elements—acids, radioactive substances, and corrosive tailings. But not one has seen sufficient explanation—from either Lynas or Malaysian officials—of exactly how it will do this.

When I ask Lynas if it has plans for a permanent waste storage facility, I receive no response. When I ask how the plant will treat its liquids for release into the river, or the radioactive solids it aims to recycle into construction materials, spokesman Alan Jury declines to provide answers and instead refers me to the International Atomic Energy Agency’s review of the plant.

I track down an engineer who worked on the Kuantan plant; he agrees to speak with me if given anonymity. Early on in the construction process, the engineer says, his team noticed serious flaws, including moisture seeps and cracks, in the 22 waste tanks the company was building. The problems led AkzoNobel, a Dutch company that Lynas had contracted to create the linings for the tanks, to pull out of the project, a story that the New York Times broke early this year. When I asked about the incident, an AkzoNobel spokeswoman wrote, “Due to changes in the Project specification, AkzoNobel would only recommend the use of its linings on the Project subject to the successful results of longer-term testing. That testing could not be completed within the project timescale.”

“My personal opinion is that the plant can operate safely,” the engineer tells me, “providing that i’s effectively engineered.” So far, though, he isn’t convinced it is.

“I don’t see the waste as impossible to manage, but you can’t do it in secret, and you can’t do it without good numbers,” agrees Gavin Mudd, a senior lecturer of civil engineering at Australia’s Monash University. “If Lynas is so confident in its methods, then it should have no problem being transparent.”

Lynas spokesman Jury says that the change of contractors was a “commercial decision” and assures me that the new one, Trepax Innovation, is lining the tanks “to meet the international industry standard.”

I attend a press conference with Raja Dato’ Abdul Aziz bin Raja Adnan, the head of Malaysia’s Atomic Energy Licensing Board, the body that subsequently granted Lynas a license to operate. I ask Aziz, who never seems to break a sweat or lose his grin as reporters pelt him with pointed questions, whether the board has looked into the plant flaws. Aziz responds that the plant has been inspected by a registered engineer. When I ask for the engineer’s name, Aziz declines to give it. Why wasn’t the report available to the public? I ask.

“Because it’s Lynas’ document,” says Aziz.

So it was Lynas that looked into the allegations made by the Dutch contractor? He demurs, so I ask again who inspected the plant.

“I looked into the allegations,” he says.

“You personally looked into them?”

“We looked into them.”

“So then why can’t you tell me the name of the engineer who inspected the building for the safety flaws?”

“That’s for you to find out.”

Right. When I later ask Jury about the alleged inspection report, he says he doesn’t have it.

On the day that I leave Malaysia, a group of Kuantan residents files suit against Lynas and the licensing board, alleging in part that the board had a conflict of interest when it made a deal to receive 0.05 percent of the plant’s revenue for “radiation research.” When the news site Malaysian Insider asks Aziz about the suit, he responds, “I don’t know anything about it.”

DOES MY PHONE HAVE TO HAVE such a toxic footprint? Not if manufacturers—and consumers—are prepared to spend more. In the shadow of the Clark mountain range in California’s Mojave Desert, about an hour outside of Las Vegas, is the Mountain Pass Mine, America’s only major rare-earth mine and refinery. Owned by a company called Molycorp, it opened in 1952 and for decades produced europium, crucial for making color TVs. But in the late ’90s, its wastewater pipes burst, and California shut the plant down; cleanup is still ongoing.

Then, in 2007, Molycorp executives decided to try to get the plant up and running again. The incentive was becoming too great. At the time, China was producing about 97 percent of the global supply of rare earths. But in 2010 it cut exports by 35 percent in order to keep the valuable metals for its own manufacturers. Prices rose and, fearing a shortage, members of Congress introduced a bill that would kick-start a domestic rare-earth renaissance by handing out federal subsidies. In March 2012, the United States, European Union, and Japan filed a formal complaint with the World Trade Organization over China’s manipulation of the rare-earth market.

By then engineers had developed several major improvements to refining methods. Molycorp’s new facility uses hydrochloric acid to remove thorium earlier in the process, when it is still in a solid state. Thorium and other waste solids are mixed into a cementlike substance, which workers spread out in layers over a 100-acre pit lined with high-density polyethylene.

Molycorp isn’t perfect. That state-of-the-art tailings field is only permitted for 30 years; after that, a new pit would need to be built. The facility uses about half the water that the old plant used, but its energy demands are seven times greater. What’s more, officials are tight-lipped about how much ore Molycorp ships to a refinery in Estonia, and about the methods used at its two Chinese refineries.

And even once Mountain Pass and other new US rare-earth plants are running at full capacity, we won’t come close to producing all the rare earths that we consume. The United States contains only 10 percent of the world’s known deposits. A recent Congressional Research Service report recommended that the US ensure reliable access to sources in countries like China, where rare earths are more abundant or—more to the point—cheaper to extract and refine. “Unless the consumers (industry or end buyers or both) demand that China and others do things in an environmentally sound manner,” Jim Kuipers, a Montana-based engineer and mining consultant, wrote me, “they’ll continue to do business as usual.”

Could recycling help? After all, Americans are buying ever more personal electronics, but only 24 states require manufacturers to pay for e-waste recycling, which means only 25 percent of electronics of any kind (and 11 percent of phones and other mobile devices) are ever even collected. What programs do exist often amount to shipping old phones and TVs to Chinese villages, where they are broken up and bathed in acid to remove gold and silver—resulting in terrible lead and dioxin pollution. Upshot: Though rare earths are recyclable, only 1 percent currently are. A bit of good news: Sick of being buffeted by China’s export policies and eager to go green, Japan’s major car companies recently began recycling the rare earths in their hybrids’ batteries. Get on it, Detroit.

ONE NIGHT TOWARD THE END of my visit to Kuantan, I’m lying in bed in a hostel in the middle of a dark neighborhood. I’ve been told that I’m the only guest tonight, and the hostel’s owner lives on the other side of town. In the middle of the night, I awake to the sound of men’s voices yelling outside my room in Mandarin. The front door slams. I sit up in bed, heart pounding. The yelling doesn’t stop, and I’m becoming increasingly panicked. Something crashes, and that’s it: I grab my phone, call Tan, and text a friend back in the States: “Don’t freak out, I’m fine, but can you look up how to make an emergency call in Malaysia just in case?” She quickly texts back, and I feel immediately better. A little while later, the hostel owner, whom Tan called, arrives. “No scared, la!” he assures me. (Malaysians often use “la” at the end of sentences for oomph.) They are just last-minute guests, tea merchants who were out partying. Very drunk but totally harmless. Mortified, I text my friend back. Then I apologize over and over—in English and tortured Malay—to the tired owner.

As I try to fall back asleep, I realize that in this situation, my phone was my security blanket. In different circumstances, it could have been my lifeline.

A few days later Tan and I meet up with a group of anti-Lynas activists, including a chatty local man named Chow Kok Chew. He explains that he moved to the area 30 years ago—from Bukit Merah. “Every day when I went to work, I saw awful smoke,” he says. “There were a lot of factories, but none had as much smoke as Asian Rare Earth.” It was hard, he says, to start a new life here on the east coast, hundreds of miles away from his hometown. But Chow built a successful career as a construction supervisor and raised three children here. Now it feels like home.

So if the plant gets built, I ask him, will he move yet again? He shakes his head. “I am old.” Still, he has been spending most of his spare time reading up about the plant—and encouraging his friends to do the same. Next month, Chow and his friends plan to shave their heads in protest. “If I don’t do something,” he says, “I’m worried that my grandson will say, ‘Grandfather, the first time you kept quiet. The second time you kept quiet, too. Why?'”

Additional reporting by Azeen Ghorayshi. Support for this story was provided by grants from the Society of Environmental Journalists and the Puffin Foundation Investigative Journalism Project. Read Kiera Butler’s dispatches from Malaysia here.